Hydraulic Shearing Machine (HVR Series)

Technical Specifications

| Length Cutting | Shearing Capacity Nominal Rake Angle | Nominal Rake Angle | Rake Angle Range | Rake Angle Stroke Per min | No. of Hold Downs | Holding Force | Power | Packing Dimension | Weight | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | in mm | Thickness in mm | in degree | in degree | Min. | Max. | In Kg. | in HP | Kg. | |||||

| M.S. | S.S | |||||||||||||

| HFR 215 | 1500 | 2 | 2 | 1.25 | 1.25 | 1°12' | 1°12' | 16 | 16 | - | - | 3 | 2000X1000X1250 | 1300 |

| HFR 220 | 2000 | 2 | 2 | 1.25 | 1.25 | 1°12' | 1°12' | 16 | 16 | - | - | 3 | 2500X1250X1500 | 1700 |

| HFR 225 | 2500 | 2 | 2 | 1.25 | 1.25 | 1°12' | 1°12' | 16 | 16 | - | - | 3 | 3000X1250X1850 | 2500 |

| HVR 312 | 1250 | 3.15 | 4 | 2 | 3.15 | 1°30' | 0.5-2° | 16 | 11 | 8 | 1200 | 3 | 1700X1250X1950 | 2000 |

| HVR 315 | 1500 | 3.15 | 4 | 2 | 3.15 | 1°30' | 0.5-2° | 15 | 10 | 9 | 1500 | 3 | 2200X1250X1950 | 2500 |

| HVR 320 | 2000 | 3.15 | 4 | 2 | 3.15 | 1°30' | 0.5-2° | 14 | 8 | 11 | 2000 | 3 | 2700X1250X1950 | 3000 |

| HVR 325 | 2500 | 3.15 | 4 | 2 | 3.15 | 1°30' | 0.5-2° | 19 | 11 | 13 | 2300 | 5 | 3200X1250X2000 | 3700 |

| HVR 330 | 3000 | 3.15 | 4 | 2 | 3.15 | 1°30' | 0.5-2° | 18 | 9 | 16 | 2600 | 5 | 3700X1400X2100 | 4250 |

| HVR 340 | 4000 | 3.15 | 4 | 2 | 3.15 | 1°30' | 0.5-2° | 15 | 8 | 20 | 3200 | 7.5 | 4700X1500X2250 | 6000 |

| HVR 415 | 1500 | 4 | 6 | 3 | 4 | 1°37' | 0.5-3° | 23 | 13 | 9 | 4500 | 7.5 | 2250X1250X2050 | 3200 |

| HVR 420 | 2000 | 4 | 6 | 3 | 4 | 1°37' | 0.5-3° | 23 | 11 | 11 | 6200 | 7.5 | 2750X1250X2100 | 3700 |

| HVR 425 | 2500 | 4 | 6 | 3 | 4 | 1°37' | 0.5-3° | 21 | 9 | 13 | 8000 | 7.5 | 3300X1400X2250 | 4200 |

| HVR 430 | 3000 | 4 | 6 | 3 | 4 | 1°37' | 0.5-3° | 23 | 10 | 16 | 10000 | 7.5 | 3700X1500X2400 | 5250 |

| HVR 440 | 4000 | 4 | 6 | 3 | 4 | 1°37' | 0.5-3° | 22 | 8 | 20 | 12000 | 10 | 4700X1650X2600 | 7200 |

| HVR 615 | 1500 | 6 | 8 | 4 | 6 | 1°45' | 0.5-3° | 23 | 13 | 9 | 6500 | 10 | 2250X1300X2100 | 3250 |

| HVR 620 | 2000 | 6 | 8 | 4 | 6 | 1°45' | 0.5-3° | 22 | 10 | 11 | 6500 | 10 | 2750X1350X2150 | 4250 |

| HVR 630 | 3000 | 6 | 8 | 4 | 6 | 1°45' | 0.5-3° | 20 | 8 | 16 | 10800 | 15 | 3800X1650X2500 | 5750 |

| HVR 640 | 4000 | 6 | 8 | 4 | 6 | 1°45' | 0.5-3° | 22 | 9 | 20 | 13600 | 20 | 4800X1700X2750 | 8250 |

| HVR 650 | 5000 | 6 | 8 | 4 | 6 | 1°45' | 0.5-3° | 21 | 7 | 24 | 16500 | 20 | 5700X1800X2850 | 11500 |

| HVR 660 | 6300 | 6 | 8 | 4 | 6 | 1°45' | 0.5-3° | 18 | 6 | 28 | 19500 | 20 | 6700X1900X2950 | 14500 |

| HVR 815 | 1500 | 8 | 10 | 6 | 8 | 2' | 0.5-3° | 15 | 8 | 9 | 10500 | 10 | 2250X1350X2100 | 4750 |

| HVR 820 | 2000 | 8 | 10 | 6 | 8 | 2' | 0.5-3° | 15 | 6 | 11 | 12000 | 15 | 2750X1450X2250 | 5700 |

| HVR 825 | 2500 | 8 | 10 | 6 | 8 | 2' | 0.5-3° | 18 | 8 | 13 | 16500 | 20 | 3300X1650X2450 | 6500 |

| HVR 830 | 3000 | 8 | 10 | 6 | 8 | 2' | 0.5-3° | 17 | 6 | 16 | 18500 | 20 | 3800X1800X2600 | 7000 |

| HVR 840 | 4000 | 8 | 10 | 6 | 8 | 2' | 0.5-3° | 15 | 5 | 20 | 23000 | 20 | 4800X1850X2800 | 9500 |

| HVR 850 | 5000 | 8 | 10 | 6 | 8 | 2' | 0.5-3° | 18 | 6 | 24 | 27000 | 25 | 5750X1950X2900 | 12250 |

| HVR 860 | 6300 | 8 | 10 | 6 | 8 | 2' | 0.5-3° | 15 | 5 | 30 | 31000 | 25 | 6750X2100X3100 | 17000 |

| HVR 1015 | 1500 | 10 | 12 | 8 | 10 | 2° | 0.5-3° | 12 | 6 | 8 | 10500 | 10 | 2250X1350X2200 | 5000 |

| HVR 1020 | 2000 | 10 | 12 | 8 | 10 | 2° | 0.5-3° | 13 | 5 | 11 | 13000 | 15 | 2750X1500X2300 | 6000 |

| HVR 1025 | 2500 | 10 | 12 | 8 | 10 | 2° | 0.5-3° | 13 | 5 | 13 | 17500 | 20 | 3300X1650X2500 | 6750 |

| HVR 1030 | 3000 | 10 | 12 | 8 | 10 | 2° | 0.5-3° | 12 | 4 | 16 | 20000 | 20 | 3800X1850X2750 | 9000 |

| HVR 1040 | 4000 | 10 | 12 | 8 | 10 | 2° | 0.5-3° | 18 | 6 | 20 | 25000 | 25 | 4800X1950X2850 | 12000 |

| HVR 1050 | 5000 | 10 | 12 | 8 | 10 | 2° | 0.5-3° | 14 | 5 | 24 | 30000 | 30 | 5750X2050X3000 | 15000 |

| HVR 1060 | 6300 | 10 | 12 | 8 | 10 | 2° | 0.5-3° | 13 | 4 | 28 | 35000 | 30 | 6750X2200X3300 | 22000 |

| HVR 1320 | 2000 | 13 | 16 | 10 | 13 | 2° | 1-3° | 13 | 6 | 11 | 16000 | 25 | 2850X1800X2600 | 9000 |

| HVR 1325 | 2500 | 13 | 16 | 10 | 13 | 2° | 1-3° | 9 | 5 | 13 | 20000 | 25 | 3350X1900X2750 | 10000 |

| HVR 1330 | 3000 | 13 | 16 | 10 | 13 | 2° | 1-3° | 8 | 4 | 16 | 25000 | 25 | 3800X1950X2850 | 11500 |

| HVR 1340 | 4000 | 13 | 16 | 10 | 13 | 2° | 1-3° | 7 | 3 | 20 | 30000 | 30 | 4800X2000X2950 | 16000 |

| HVR 1350 | 5000 | 13 | 16 | 10 | 13 | 2° | 1-3° | 9 | 4 | 24 | 35000 | 40 | 5750X2150X3150 | 21000 |

| HVR 1360 | 6300 | 13 | 16 | 10 | 13 | 2° | 1-3° | 8 | 4 | 28 | 40000 | 40 | 6750X2300X3500 | 28000 |

| HVR 1620 | 2000 | 16 | 20 | 13 | 16 | 2° | 1-3° | 9 | 5 | 11 | 20000 | 30 | 3000X1900X2800 | 10500 |

| HVR 1625 | 2500 | 16 | 20 | 13 | 16 | 2° | 1-3° | 9 | 4 | 13 | 25000 | 30 | 3500X2000X2900 | 12250 |

| HVR 1630 | 3000 | 16 | 20 | 13 | 16 | 2° | 1-3° | 8 | 4 | 16 | 28000 | 30 | 4000X2000X3000 | 14500 |

| HVR 1640 | 4000 | 16 | 20 | 13 | 16 | 2° | 1-3° | 6 | 3 | 20 | 33000 | 30 | 4800X2050X3100 | 19000 |

| HVR 1650 | 5000 | 16 | 20 | 13 | 16 | 2° | 1-3° | 7 | 3 | 24 | 38000 | 40 | 5750X2250X3300 | 26000 |

| HVR 1660 | 6300 | 16 | 20 | 13 | 16 | 2° | 1-3° | 6 | 3 | 28 | 43000 | 40 | 6750X2350X3700 | 31500 |

| HVR 2025 | 2500 | 20 | 25 | 16 | 20 | 2° | 1-3° | 6 | 3 | 13 | 28000 | 40 | 3500X2000X3000 | 16000 |

| HVR 2030 | 3000 | 20 | 25 | 16 | 20 | 2° | 1-3° | 6 | 2 | 16 | 35000 | 40 | 4000X2100X3200 | 19500 |

| HVR 2040 | 4000 | 20 | 25 | 16 | 20 | 2° | 1-3° | 5 | 2 | 20 | 40000 | 50 | 4800X2200X3300 | 23500 |

| HVR 2050 | 5000 | 20 | 25 | 16 | 20 | 2° | 1-3° | 6 | 3 | 24 | 45000 | 60 | 5800X2350X3500 | 30000 |

| HVR 2060 | 6300 | 20 | 25 | 16 | 20 | 2° | 1-3° | 5 | 2 | 28 | 50000 | 60 | 6800X2450X4100 | 36000 |

| HVR 2525 | 2500 | 25 | 30 | 20 | 25 | 2° | 1-3° | 5 | 3 | 13 | 36000 | 60 | 3400X2250X3300 | 22000 |

| HVR 2530 | 3000 | 25 | 30 | 20 | 25 | 2° | 1-3° | 4 | 2 | 16 | 45000 | 60 | 4000X2300X3300 | 25500 |

| HVR 2540 | 4000 | 25 | 30 | 20 | 25 | 2° | 1-3° | 5 | 2 | 20 | 50000 | 75 | 5000X2300X3500 | 31000 |

| HVR 2550 | 5000 | 25 | 30 | 20 | 25 | 2° | 1-3° | 4 | 2 | 24 | 55000 | 75 | 6000X2450X3700 | 36000 |

| HVR 2560 | 6300 | 25 | 30 | 20 | 25 | 2° | 1-3° | 3 | 1 | 28 | 60000 | 75 | 7000X2600X4300 | 42000 |

*Specifications are subject to changed without prior notice.

Accessories

Standard :

- Electric control panel

- Hardened transfer bars mounted on table

- Rake angle selection through selector switch

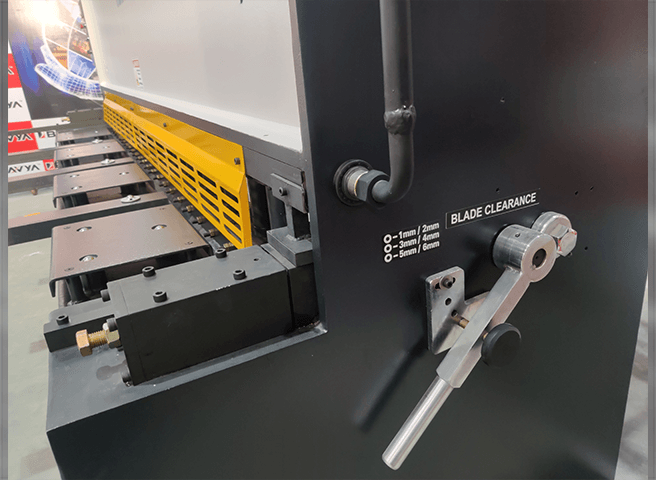

- Lever operated blade clearance with calibration

- Fine stroke adjustment rod with limit switch

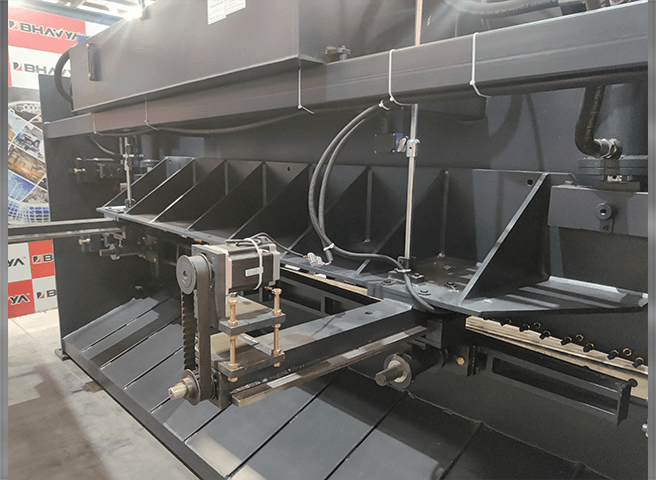

- Back gauge on double guide rods & lead screw

- Front sheet support

- Squaring arm with steel ruler on left side

- Hold down cylinders mounted on machine

- Four edge HCHCr blade suitable to cut MS & SS Material**

- Manual back gauge

Optional :

- Motorized back gauge with DRO

- Second squaring arm on other side

- Front support with roller according to required length

- Rear Sheet support

- Timer belt drive for back gauge

- Ball Transfer Table

- Degree protector for angular cutting

- Stroke counter

- Design with throat depth

- First fill of Hydraulic oil

Features

- Guillotine type hydraulically variable rake angle design

- Twist free & better cutting result in thin sheets at lower rake angle

- Cutting job accuracy as per DIN Standard

- Higher cutting capacity than rated capacity at higher rake angle

- The stable & robust structure from ultrasonically & tensile tested IS:2062 grade steel

- Rigid box type structure of ram & table with inclined member in direction of resultant force

- Hydraulic & electrical safety interlocks for overloading.

- NC up-gradation possible

- Bolted type Square Box assembly for holding cylinder mounting

- Special guided seal for holding cylinder to avoid leakage

- All Electrical & hydraulic component from reputed make

- Ram quided six hardened & grounded guide rollers

- Suitable for upgradation with special optional features

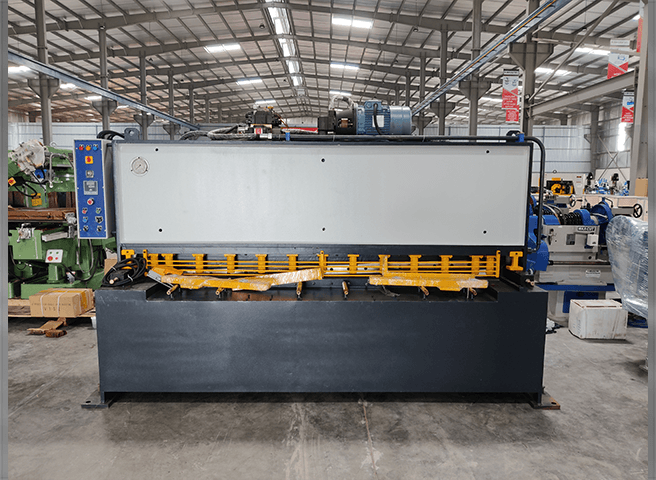

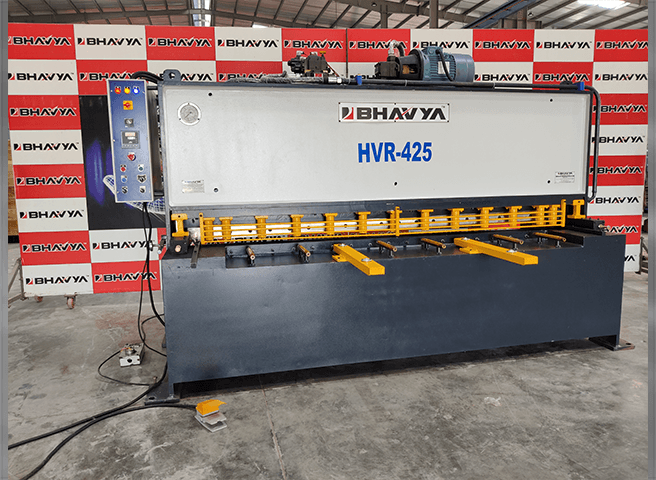

Photo Gallery

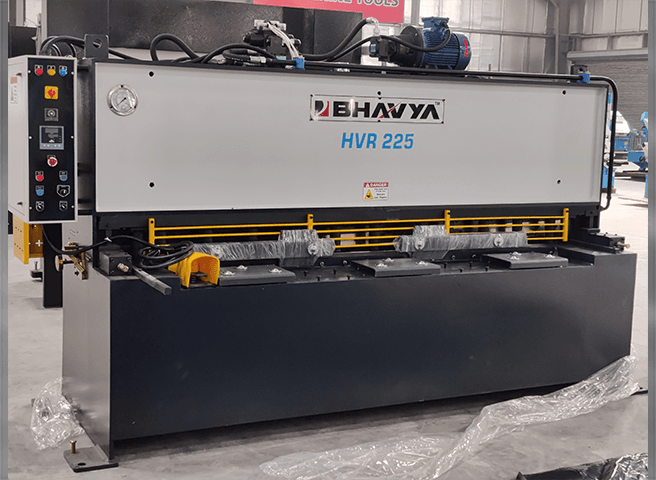

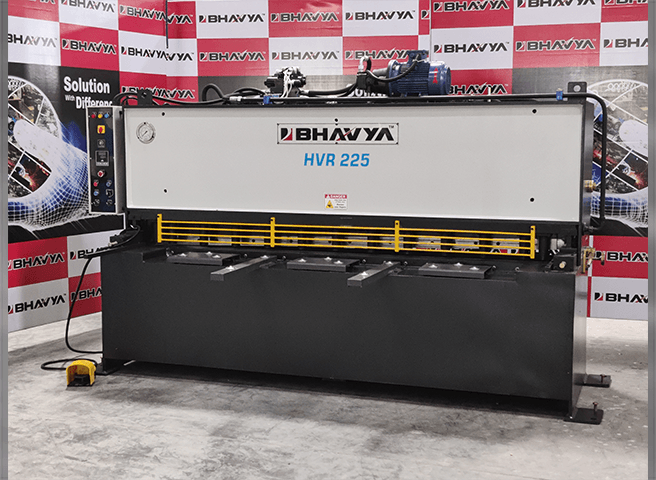

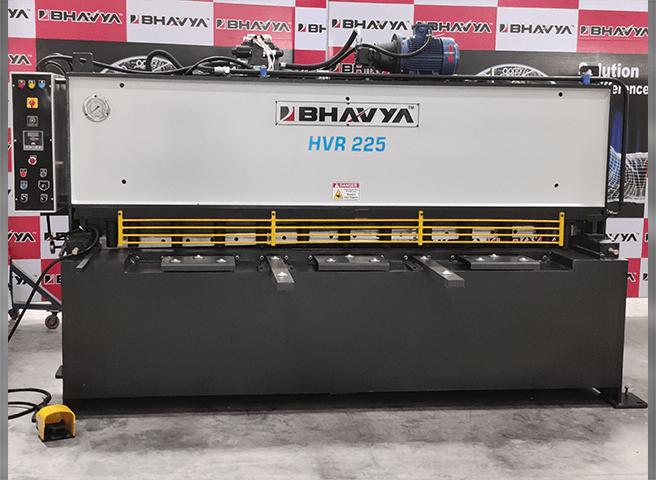

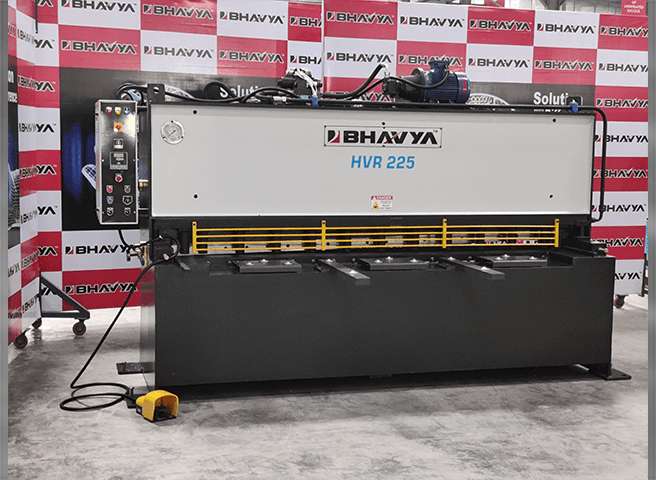

HVR 225

HVR 225

HVR 225

HVR 225

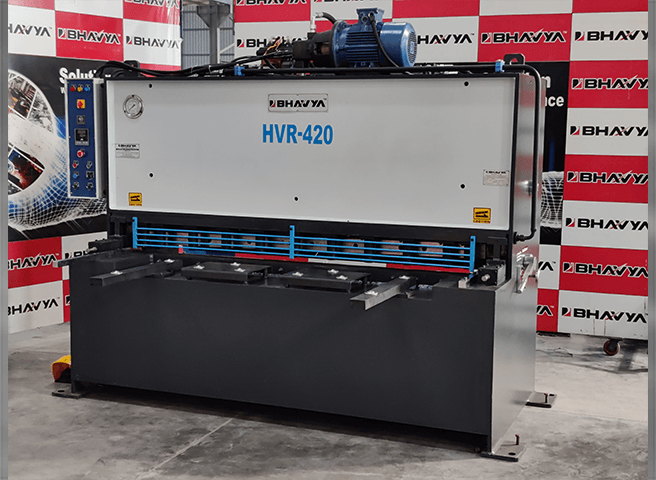

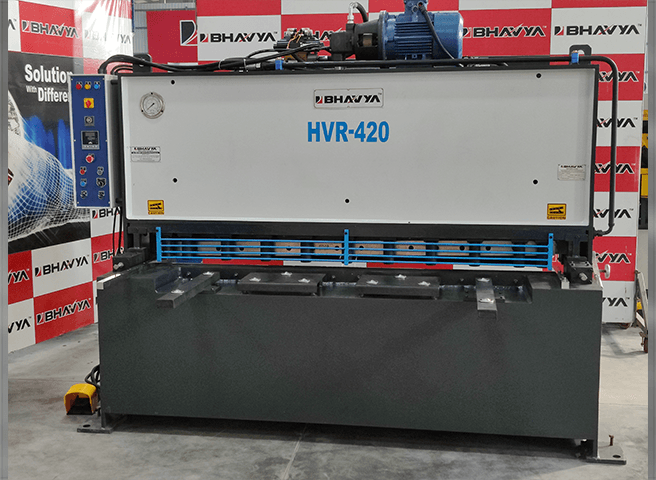

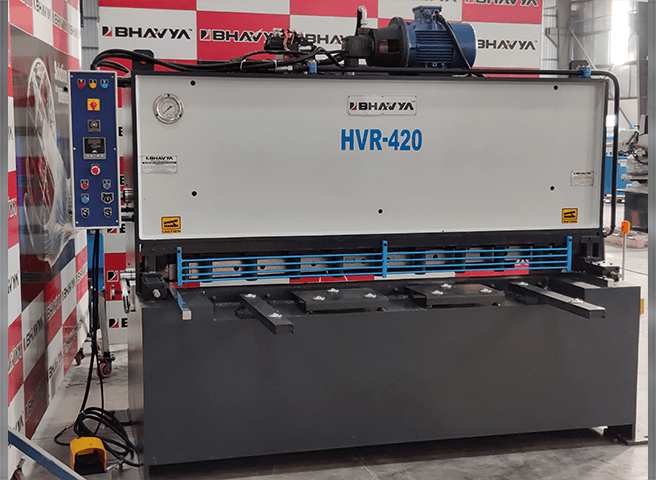

HVR 420

HVR 420

HVR 420

HVR 425

HVR 425

HVR 425

HVR 425

HVR 430

HVR 430

HVR 430

HVR 430

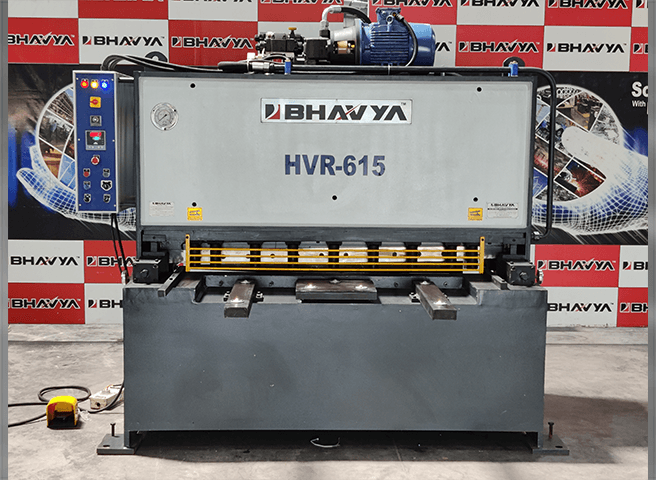

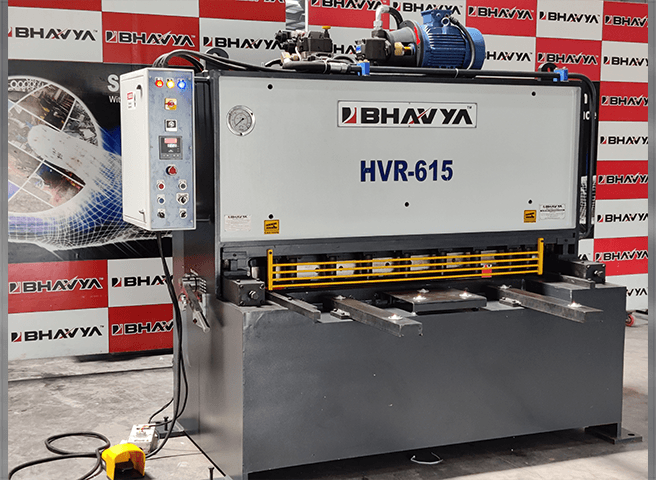

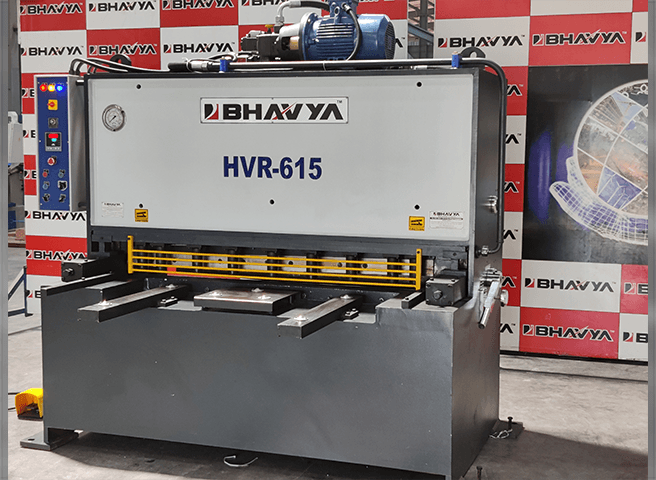

HVR 615

HVR 615

HVR 615

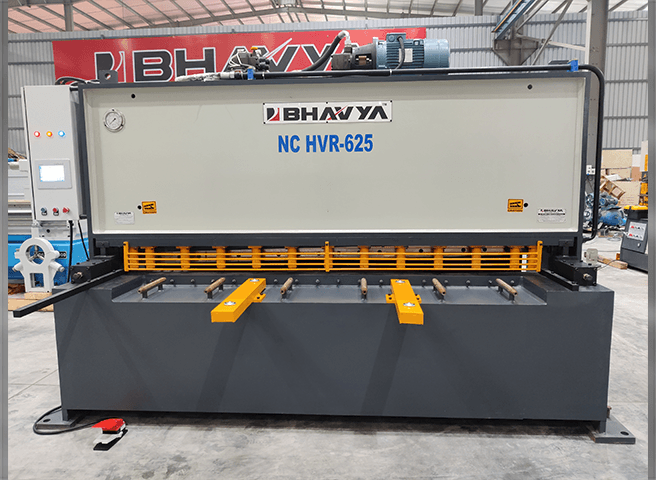

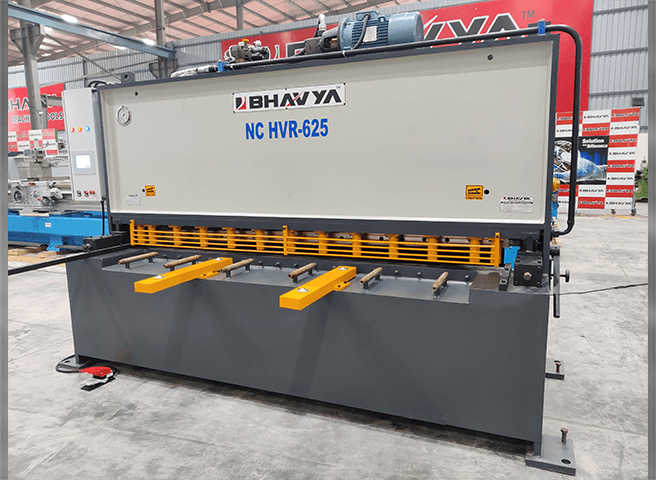

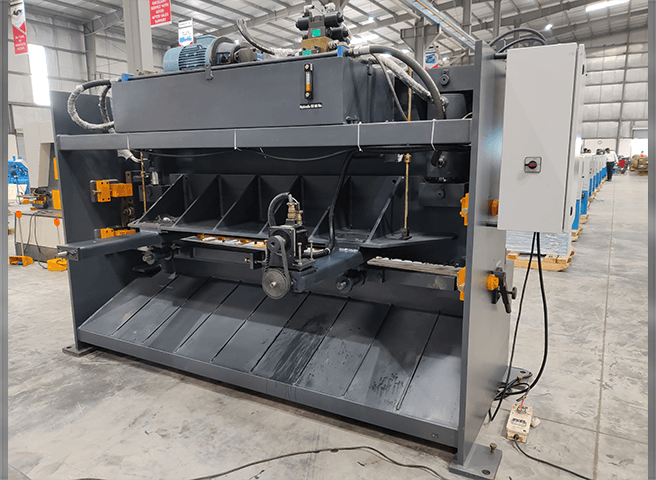

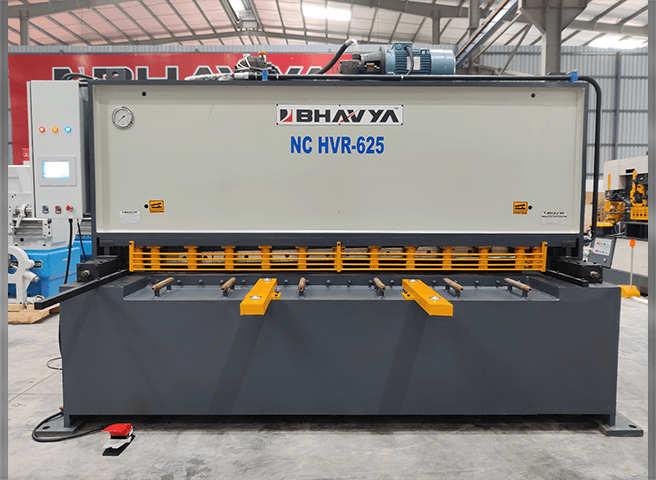

HVR 625

HVR 625

HVR 625

HVR 625

HVR 1015

HVR 1015

Videos

Hydraulic Shearing Machine