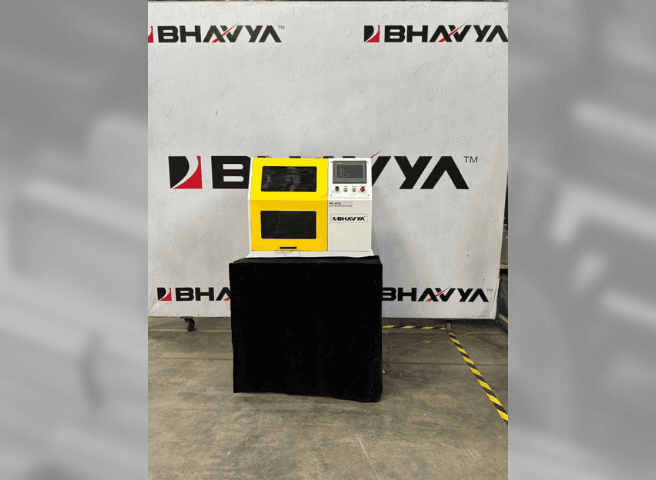

CNC RESHARPENING MACHINE (4 Axis) (ENDMILL-BALL NOSE & DRILL BITS)

Technical Specifications

| Model | AE30 |

|---|---|

| Diameter range Endmill | Φ4-Φ20 |

| Diameter range Ballnose | Φ4-Φ20 |

| Diameter range Drill bit | Φ4-Φ20 |

| Power | 220V/750W |

| Servo System | 4 Axis (X, Y, Z, C Rotation Angle) |

| Operating HMI | Touch Screen |

| Speed | 3300rpm |

| Grinding Time | 1-3 Min. |

| Grinding Wheel | SDC FOR CARBIDE |

| Grinding Wheel Size | 125 x 10 x 32 mm |

| Weight | 65 kg |

| DELIVERY TIME | READY STOCK |

*Specifications are subject to changed without prior notice.

Accessories

- ER32 COLLETS: Ф4, Ф6, Ф8, Ф10, Ф12, Ф14, Ф16, Ф18, Ф20

- SD Grinding Wheel (For Carbide Cutter) – 1 Nos

- Collet Holder – 1 Nos

- User Manual

Features

- AE – 30 Automatic milling cutter sharpeners, through program control, can quickly grind 2/3/4-edge milling cutters with a diameter of 4-20mm. After the clamping is completed, the milling cutter automatically sets the tool and completes the grinding of the tool edge and end face in one go. Suitable for large-volume repair of milling cutters such as CNC machining centers. After grinding, the milling cutter can be put into CNC processing production, which greatly extends the service life of the milling cutter and reduces the cost of tool use.

- High precision servo motor Position and speed multi-stage control. Equipped with overload and overvoltage protection to ensure long-term operation.

- It can be equipped directly with an accurate angle and long service life.

- With diamond grinding wheel, only one piece can complete all procedures.

- Grinding is accurate and rapid, easy operation, with no skill requirement to grind easily.

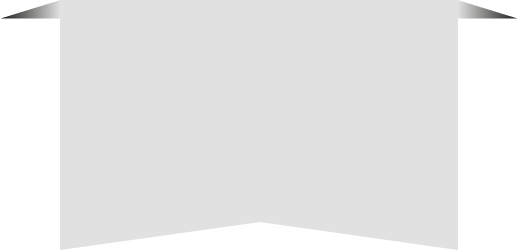

Photo Gallery

CNC RESHARPENING MACHINE

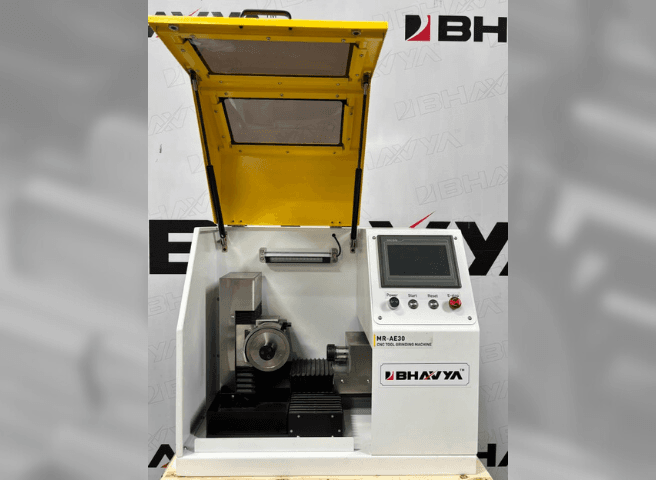

CNC RESHARPENING MACHINE

CNC RESHARPENING MACHINE

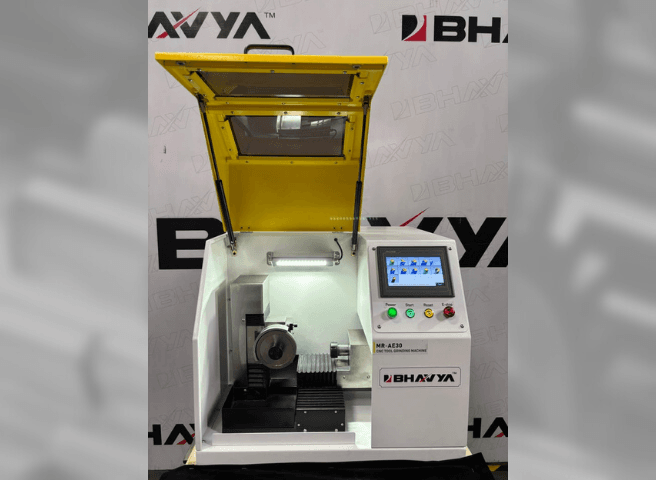

CNC RESHARPENING MACHINE

CNC RESHARPENING MACHINE

CNC RESHARPENING MACHINE

CNC RESHARPENING MACHINE

CNC RESHARPENING MACHINE