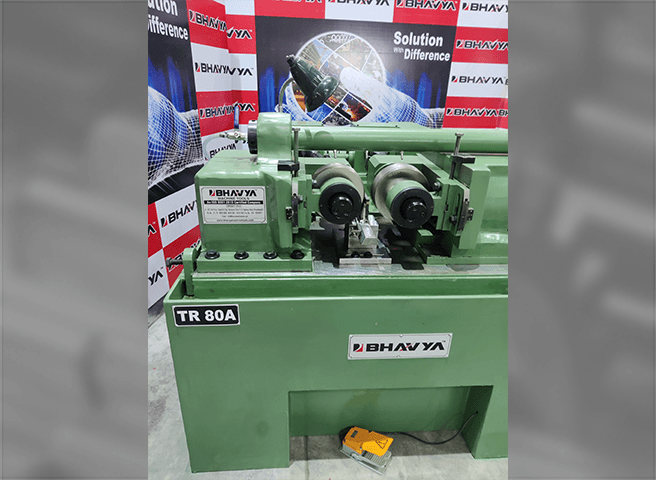

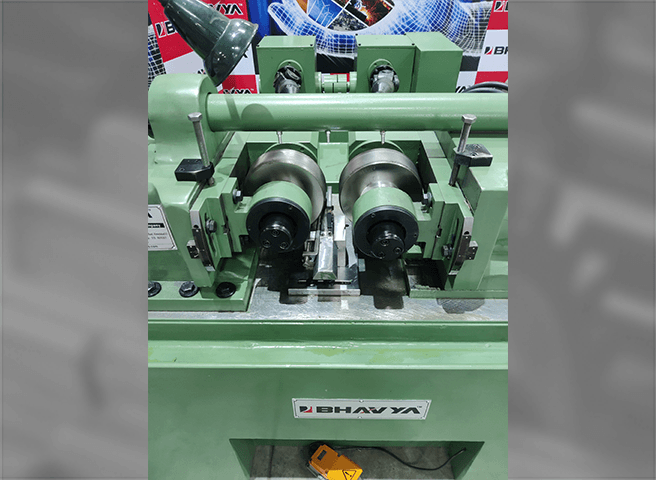

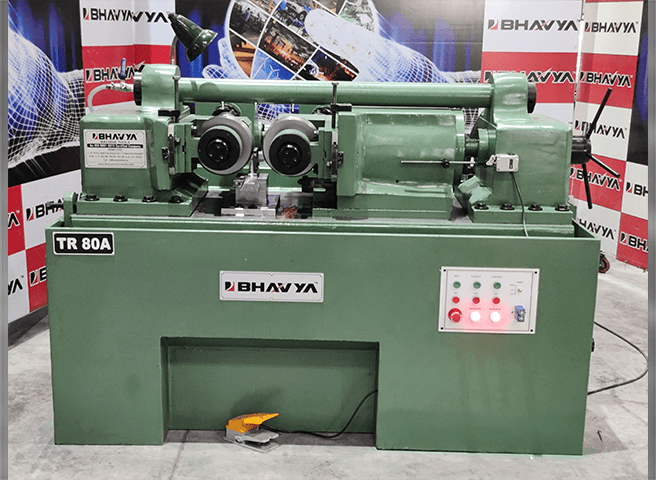

Hydraulic Thread And Form Rolling Machine

Technical Specifications

| Model | TR-25 | TR-30 | TR-40 | TR-50 | TR-80 | TR-190 | TR-120 |

|---|---|---|---|---|---|---|---|

| Max. Pitch Can Be Rolled (in mm) | 3 | 25 | 35 | 4 | 5 | 6 | 8 |

| Max. Dia can be Rolled in Feed (in mm) | 25 | 30 | 40 | 50 | 80 | 100 | 120 |

| Max. Dia can be Rolled in Through Feed (in mm) | 18 | 20 | 28 | 35 | 40 | 50 | 70 |

| Max. Rolling Length in Feed (in mm) | 80 | 100 | 100 | 150 | 150 | 150 | 70 |

| Max. Rolling Length Through Feed | Indefinite | Indefinite | Indefinite | Indefinite | Indefinite | Indefinite | Indefinite |

| Max. Outer Dia of Thread Rolls (in mm) | 120 | 160 | 180 | 200 | 230 | 230 | 230 |

| Spindle Dia (Bore Dia) (in mm) | 40 | 54 | 54 | 54 | 69.85 | 76.20 | 76.20 |

| Max. Width of Thread Rolls (in mm) | 80 | 100 | 100 | 140 | 150 | 150 | 150 |

| Max. Rolling Force (Tons) | 8 Tons | 10 Tons | 12 Tons | 15 Tons | 24 Tons | 30 Tons | 40 Tons |

| Power For Roll Spindles | 3 H.P. | 3 H.P. | 5 H.P. | 7.5 H.P. | 10 H.P. | 12.5 H.P. | 20 H.P. |

| 1440rpm | 1440rpm | 1440rpm | 1440rpm | 1440rpm | 1440rpm | 1440rpm | |

| Power For Hydraulic Pump | 2 H.P./3 H.P. | 2 H.P./3 H.P. | 2 H.P./3 H.P. | 3 H.P. | 3 H.P./7.5 H.P. | 5 H.P./7.5 H.P. | 7.5 H.P. |

| 960/1440 | 960/1440 | 960/1440 | 960/1440 | 960/1440 | 960/1440 | 960/1440 | |

| RPM | RPM | RPM | RPM | RPM | RPM | RPM | |

| Power For Coolant Pump | 0.1 H.P. | 0.1 H.P. | 0.1 H.P. | 0.1 H.P. | 0.1 H.P. | 0.1 H.P. | 0.1 H.P. |

| 3000 RPM | 3000 RPM | 3000 RPM | 3000 RPM | 3000 RPM | 3000 RPM | 3000 RPM |

*Specifications are subject to changed without prior notice.

Features

- Compact Design

- Fabricated steel frame

- Versatile for all type of works

- Manual & Automatic cycles

- Range of cycle times

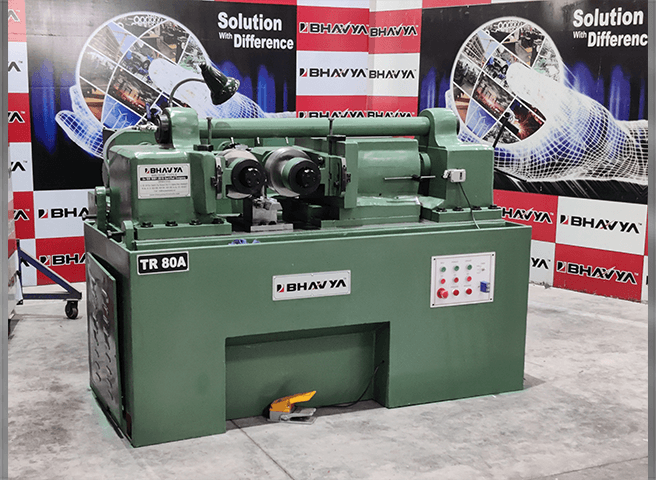

- Extended universal joint provides smooth operation for big angle of work piece

- Over sized coolant tank for superior cooling effects

- Low pressure hydraulic power pack to ensure to low heat & minimum maintenance

- CT" type and accurately ground slide assures that jumping and vibration will not happen during rolling

- Centralized lubrication of all important moving parts

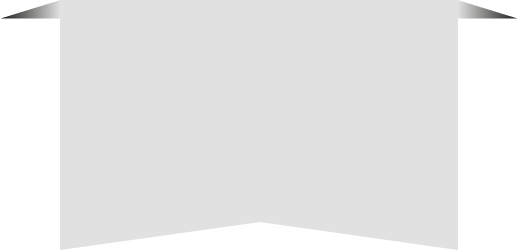

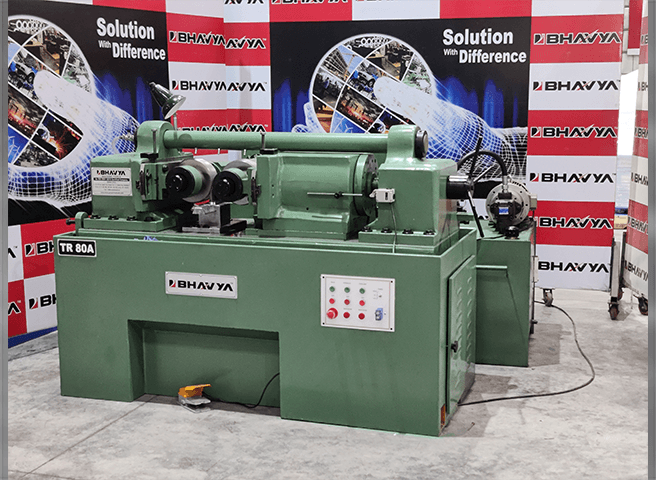

Photo Gallery

TR-80

TR-80

TR-80

TR-80

TR-80

TR-80

TR-80